Refrigeration systems for low-temperature storage

In distribution centers, the efficiency of refrigeration systems is a decisive factor in preserving perishable products. Food, pharmaceuticals, and other sensitive items rely on strict temperature control to maintain quality, prevent waste, and ensure they reach the end consumer in perfect condition.

In this article, we will explore how these systems work, the challenges they face, and the best practices for safe and efficient temperature-controlled storage.

How do deep freeze refrigeration systems work?

Cold storage systems designed for low temperatures operate below freezing, ensuring the proper preservation of perishable goods. For frozen food, for example, the ideal temperature range is between 0°F and -13°F (-18°C to -25°C), preventing any loss of freshness or quality.

In industrial cold storage facilities, these systems must be highly efficient and robust, handling large volumes of goods while maintaining optimal conditions from reception to dispatch.

The importance of cold storage technology in distribution centers

Cold storage technology plays a fundamental role in distribution centers for several reasons. It ensures the proper conservation of food, pharmaceuticals, and other temperature-sensitive products, maintaining their quality from storage to transport. Moreover, these systems comply with stringent food and pharmaceutical industry regulations, ensuring adherence to sanitary standards.

Another crucial factor is logistics optimization. A well-regulated temperature-controlled storage environment prevents fluctuations that could compromise product integrity, making operations more efficient and secure.

Challenges in refrigeration systems

Despite their importance, refrigeration systems face several challenges that require careful management:

- High energy consumption: maintaining extremely low temperatures demands significant energy usage, making energy efficiency a critical factor.

- Risk of technical failures: a system failure can lead to substantial product losses.

- Temperature fluctuations: frequent opening and closing of cold storage rooms can disrupt thermal stability, affecting product preservation.

How to ensure efficient frozen storage solutions?

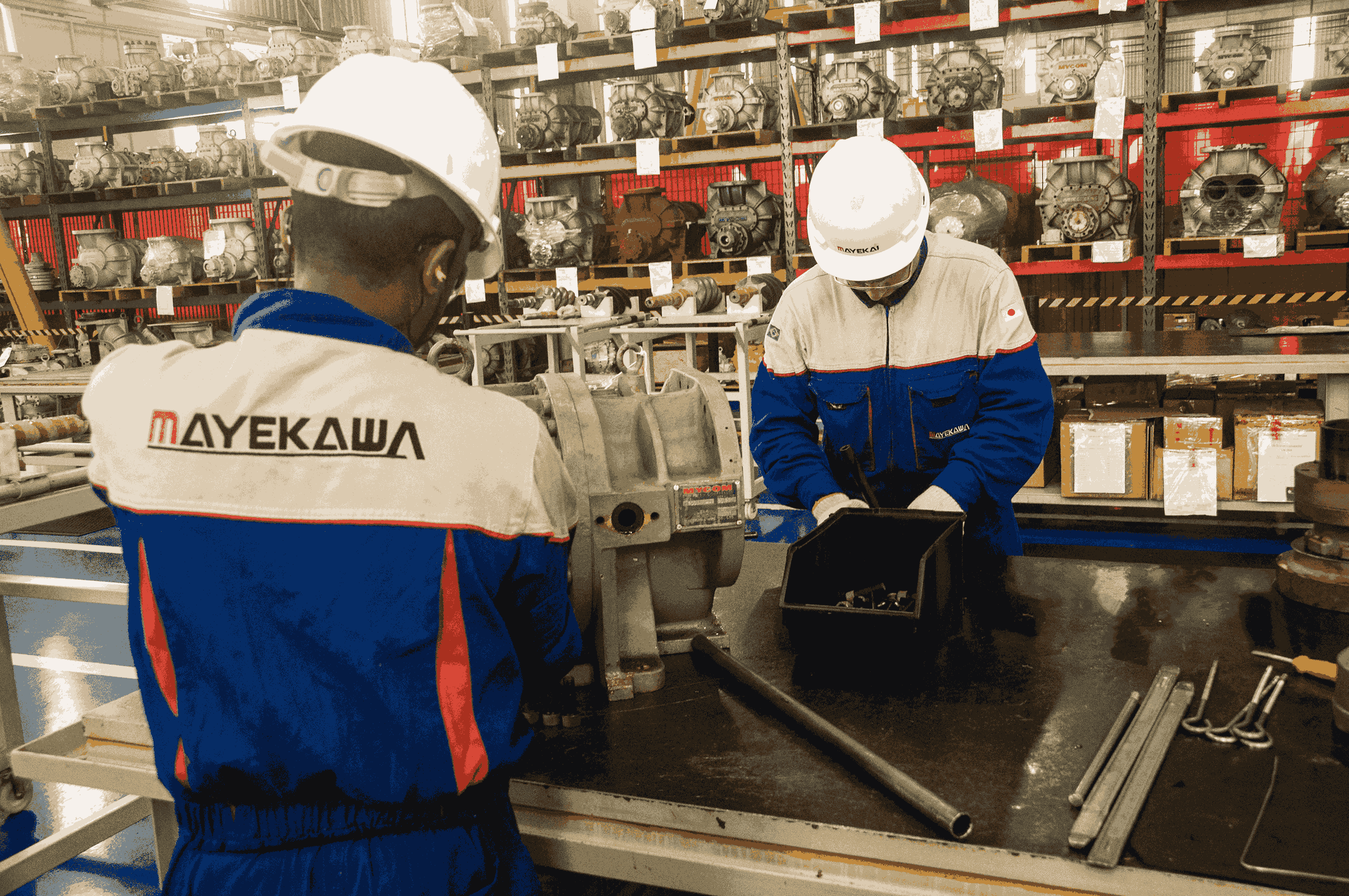

To maximize efficiency in industrial cold storage, several factors must be considered. The first is a well-designed facility, with insulated cold rooms structured to minimize thermal losses. Additionally, adopting advanced technologies, such as automated control systems, enhances performance while reducing energy consumption.

Another essential aspect is preventive maintenance. Regular inspections ensure that equipment operates reliably and without unexpected breakdowns. Furthermore, training operators to properly handle cold storage systems is crucial for daily management, preventing errors and waste.

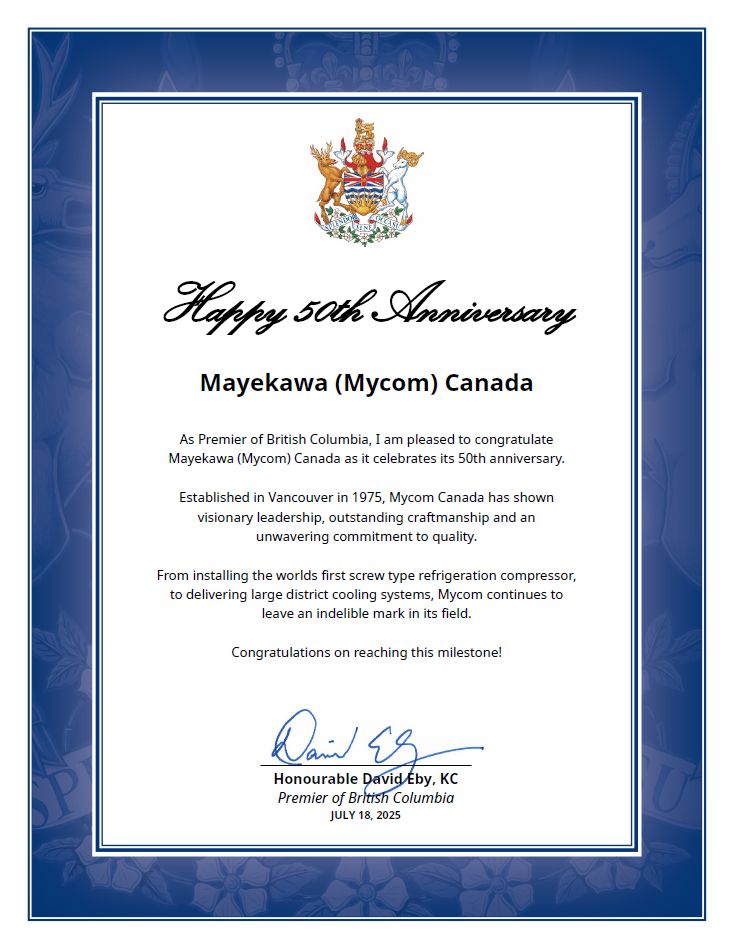

Efficiency and competitiveness in the cold chain

Deep freeze refrigeration is the backbone of any distribution center handling perishable goods. It ensures product preservation, optimizes logistics, and guarantees compliance with essential regulations.

Investing in technology, preventive maintenance, and team training is key to maintaining an efficient, sustainable, and reliable system. In a world where the cold chain directly impacts product quality, having a robust cold storage technology system is not just a necessity—it is a competitive advantage.

To learn more about our cold storage solutions, explore our cold storage applications. If you’re looking for cutting-edge refrigeration technology, check out our refrigeration products and freezer systems.