Maintaining equipment in optimal working condition is not only a matter of operational efficiency but also of cost-effectiveness and safety. Predictive maintenance for chillers is a vital strategy for identifying and addressing potential failures before they result in significant damage. This article will explore how this approach can make a substantial difference, particularly in distribution centers, where every moment of operation is crucial.

Predictive maintenance: why should this strategy be adopted?

Predictive maintenance leverages advanced technology to monitor equipment in real-time, analyzing key data such as temperature, pressure, and vibration. The objective is to identify signs of wear before catastrophic failures occur.

In contrast to corrective maintenance (which is conducted only after a failure) and preventive maintenance (which follows a fixed schedule), predictive maintenance enables precise interventions, thereby reducing unnecessary costs and optimizing equipment usage.

In distribution centers, where continuous operation is paramount, this strategy is indispensable for preventing unexpected shutdowns, safeguarding equipment, and ensuring operational efficiency.

The importance of industrial chillers in operational efficiency

Among the most vital equipment in distribution centers are industrial chillers, which are essential for the proper functioning of refrigeration systems. A failure in a chiller can compromise the entire process, leading to delays and substantial financial losses.

Maintaining chillers in optimal condition is not simply a recommendation—it is an imperative to guarantee secure and uninterrupted operations. For optimal refrigeration system maintenance, including specialized ammonia chiller maintenance, please visit our dedicated support page.

How predictive maintenance works for industrial chillers?

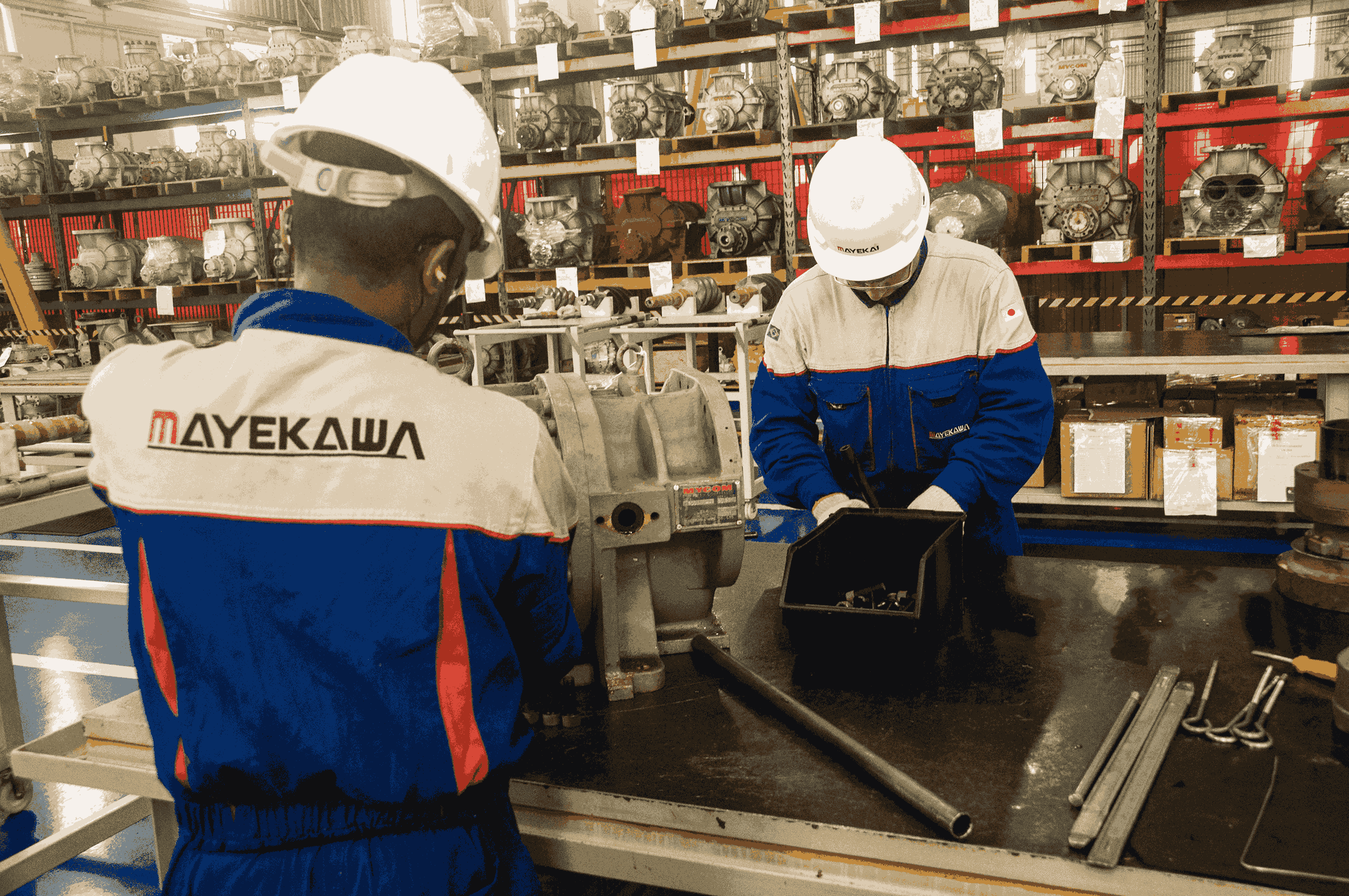

Predictive maintenance for industrial chillers incorporates a range of advanced practices and technologies to ensure peak performance. This includes:

- Continuous monitoring of pressure, temperature, and vibration to detect anomalies before they evolve into critical issues.

- Detailed inspection of filters, valves, and belts to prevent blockages and premature wear.

- Oil quality analysis to ensure proper lubrication and to avoid overheating.

- Precise alignment between the motor and chiller to minimize wear and reduce excessive energy consumption.

- Leak detection to prevent inefficiencies that could raise operational costs.

Utilization of smart sensors and predictive software to generate real-time reports, facilitating informed decision-making.

By incorporating these practices, industrial chillers can operate at maximum efficiency, minimizing unexpected failures and drastically reducing maintenance and repair costs.

Benefits of predictive maintenance for distribution centers

Companies that implement predictive maintenance for their refrigeration systems, including industrial chiller systems, experience numerous advantages, such as:

- Extended Equipment Lifespan – Minor adjustments prevent extensive damage, thus prolonging the durability of industrial chillers.

- Reduced Operational Costs – Anticipating and addressing potential issues proactively minimizes costly emergency repairs and costly downtime.

- Improved Operational Efficiency – The foresight to predict equipment failures allows for uninterrupted operations, ensuring a smooth and continuous workflow.

- Sustainability – Properly maintained equipment consumes less energy, thereby reducing both operational costs and environmental impact.

Anticipating Failures: A Synonym for Efficiency and Cost Savings

Predictive maintenance has transitioned from being a competitive advantage to becoming a necessity for organizations striving to optimize operations and reduce costs. Specifically, for industrial chiller maintenance, this approach guarantees stable and efficient functionality over the years, preventing premature replacements and unplanned shutdowns.

Investing in specialized technical services, including chiller maintenance and predictive maintenance for cooling systems, not only preserves your equipment but also enhances productivity. It is essential to remember that preventive maintenance for cooling systems is always more cost-effective than corrective measures.

Would you like to learn more about best practices for industrial equipment maintenance? Continue following our blog for expert insights on chiller and cooling system maintenance, including chilled water pump maintenance.